Rock Candy

Monday, September 25, 2006What do you get when you mix maple candy with granite tombstones?

Our last day in Vermont…

Driving down to the central part of the state, we started with a short tour of the Maple Grove Farms Factory & Museum. Maple Grove Farms, located in St. Johnsbury, Maine, is the producer of all of the maple syrup used by Cracker Barrel – nearly 20% of the entire US annual output. The factory also produces several lines of salad dressings, but most importantly, what we came for – maple candy.

Driving down to the central part of the state, we started with a short tour of the Maple Grove Farms Factory & Museum. Maple Grove Farms, located in St. Johnsbury, Maine, is the producer of all of the maple syrup used by Cracker Barrel – nearly 20% of the entire US annual output. The factory also produces several lines of salad dressings, but most importantly, what we came for – maple candy.The tour consists of a short video on the company’s history, and a walkthrough by a small production line creating the maple candy (yummy!). The tour lasts just a few minutes, but it’s only a dollar, making it pretty much the best bang for the buck in the area.

Maple syrup comes from the sap of sugar maples. We were surprised to learn that the trees are tapped in early spring when the sap begins to rise from the roots. Both Denise and I had always supposed sap collection occurred in the fall, a common misperception for southerners (in the south, syrup is made from cane harvested in the fall). It takes on average 40 gallons of sap to create 1 gallon of syrup, so you can imagine how many trees get tapped to keep our pancake eating populace happy. Once the sap is collected, it is immediately boiled down to create multiple grades of syrup, in a process called syruping.

The factory’s role is more packaging and quality control for the maple syrup than production. To make candy, the syrup is heated to a temperature where it forms a dough-like substance (fundament). After stirring, the fundament is packed into molds, then dipped into vats of maple syrup overnight to coat and preserve. A surprising fact is all of the candy is hand packed. We saw tables surrounded by ladies picking up and packing the candy, in what must be the most diabetes inducing job in America.

Hairnets are required for the tour, and I had to wear a beard-net, which Vance thought was the funniest thing he’d seen in quite awhile.

The best part was at the end, however, in a small log cabin containing the museum. Standing outside the building, the plaintive sound of a lone fiddle filled the fall air. Thinking it sounded awfully good for a recording, we stepped inside to find David Carpenter, dance fiddler.

David was kind enough to spend the next quarter hour or so explaining the syruping process to us from a historical perspective, after entertaining us with several fiddle tunes. He also turned out to be a treasure chest of information about the back roads of Vermont, giving me enough pointers on out of the way drives to keep us busy for a couple of more weeks! We purchased one of his CD’s, full of New England fiddle dance tunes, some of his own composition. We’ve listened to it over and over, as it provides the perfect backdrop when viewing the fall color.

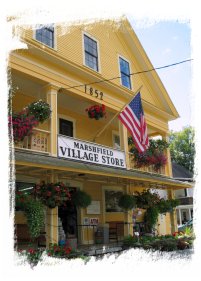

Moving onward, we stopped for lunch at the Marshfield General Store. . Somehow New England has managed to preserve the idea of the village general store. Every village has one of these gems – always in a wonderful old building, stocked with pretty well everything you’d expect at a convenience store, a good wine/beer selection, and a small dining section selling pizza and/or sandwiches (called grinders up here). The urge to just hang around and talk is almost overwhelming in such places, and it’s a real shame we have to settle for tacky Exxon stations serving greasy chicken back home in the South.

So where do the tombstones come in?

The Rock of Ages Quarry in Barre, Vermont, is the deepest dimensional granite quarry in the world. I never did find out exactly what made the quarry dimensional, other than they saw and blast the granite out in very large rectangular chunks. The quarry, which offers tours, is over 600 feet deep. The vein of granite is large enough that it will take 4500 years at the current mining rate to deplete the vein.

It’s an interesting tour, if nothing else to see how such a large chunk of rock is cut out of a big hole. It takes about 6 weeks to cut out a large block, which is then sliced into smaller pieces for lifting out of the quarry. The large granite slabs will later be cut down to size for usage as tombstones or other memorials. The factory uses granite from multiple quarries, each having a particular color (shades of grey, pink, brown, and black).

The real interesting part of the tour was viewing the factory, where the tombstones are created. There is a viewing area running above on side of the factory floor, with explanations on how names, dates and figures are carved into the stone. The stones are first cut (using diamond tipped bandsaws) flat on two sides, then polished, finally cut again into the outline of the tombstone. Letters and decorations are usually sandblasted into the stone. Artisans create stencils for the sandblasting (an inverse image of what is to be cut out), and rubber stencils are created and carefully positioned onto the tombstone. The process isn’t all that different than what Vance did to sandblast a coffee cup at the Corning Museum of Glass, only on a larger scale.

The real interesting part of the tour was viewing the factory, where the tombstones are created. There is a viewing area running above on side of the factory floor, with explanations on how names, dates and figures are carved into the stone. The stones are first cut (using diamond tipped bandsaws) flat on two sides, then polished, finally cut again into the outline of the tombstone. Letters and decorations are usually sandblasted into the stone. Artisans create stencils for the sandblasting (an inverse image of what is to be cut out), and rubber stencils are created and carefully positioned onto the tombstone. The process isn’t all that different than what Vance did to sandblast a coffee cup at the Corning Museum of Glass, only on a larger scale.Elaborate figures may take multiple passes in the sandblasting area, with multiple stencils, to get a 3 dimensional effect (for example, flowers that are rounded going into the stone). Somewhat to my surprise, figurines and statues are still hand carved, and there was an area with workers chiseling away at the granite, much like they must have done several hundred years ago.

It’s a bit surreal to stand gawking down while someone’s tombstone is being created, but it was undeniably interesting to watch. The factory floor is very noisy, with all of the sandblasting and the sawing of solid rock going on.

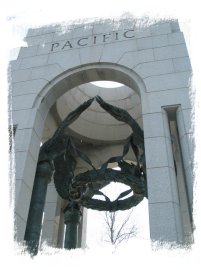

It’s a bit surreal to stand gawking down while someone’s tombstone is being created, but it was undeniably interesting to watch. The factory floor is very noisy, with all of the sandblasting and the sawing of solid rock going on. Tombstones aren’t the only product from Rock of Ages. They also create custom memorials – one of the largest jobs they’ve done lately was create the pavilions for the WWII Memorial on the Mall in Washington D.C. which we saw last year. Although the granite for the memorial came from South Carolina, the carving was done at the Rock of Ages facility in Barre, VT.

Tombstones aren’t the only product from Rock of Ages. They also create custom memorials – one of the largest jobs they’ve done lately was create the pavilions for the WWII Memorial on the Mall in Washington D.C. which we saw last year. Although the granite for the memorial came from South Carolina, the carving was done at the Rock of Ages facility in Barre, VT.At one point Rock of Ages tried to interest bowling alleys in using Granite for the lanes, to reduce maintenance costs. The idea never caught on, but they built an outdoor lane adjacent to the factory to demonstrate the concept. Today, they allow visitors to play on the lane, and Vance had a great time bowling.

We ended the day with a quick swing thru Montpelier, the capital of Vermont. Montpelier is the smallest capital in the US, hardly more than a large village. But the capital building, constructed with granite from the Barre quarries, is simply beautiful. Many of the state office buildings surrounding the capital are Victorian structures that look like large homes, and the governor’s office is located in a building next door to the capital that used to be a large hotel. It’s quite a change from the normal drab government buildings you see in many capitals.

We ended the day with a quick swing thru Montpelier, the capital of Vermont. Montpelier is the smallest capital in the US, hardly more than a large village. But the capital building, constructed with granite from the Barre quarries, is simply beautiful. Many of the state office buildings surrounding the capital are Victorian structures that look like large homes, and the governor’s office is located in a building next door to the capital that used to be a large hotel. It’s quite a change from the normal drab government buildings you see in many capitals.

Vance: Rock of Ages and the Maple Candy museum were quite interesting. First we went to the Maple factory and went on a tour. They had to heat and stir the maple syrup till it turns into a kind of dough. Next they formed the shape and placed it in maple syrup for about a day. The next day “voila” - you have maple candy!

Rock of Ages was a very big granite quarry. The quarry was about 600 feet deep. Granite used to make the WW2 memorial in D.C came from the quarry. We saw the working area where they carved the stones. Mostly they were making tombstones. Later we saw the quarry and went bowling on a granite alley. Finally, we went to

GRANITE AND SYRUP

<< Home